It can be argued that construction is just another distinct form of manufacturing where,

- Product is stationary (product is a ‘house’ – for example)

- Product is highly customized to the customer’s needs

- Product design can change even as the product is being manufactured (!!)

- Different contractors are tasked to make different parts of the same product

- Almost each product is unique and follows a new design each time

When construction businesses try to work with tools that have worked well in the manufacturing businesses, they are also assuming construction to be just another variant of manufacturing.

But that may not be such a good idea if you consider the differences between construction and manufacturing – especially from the communication angle.

“Imagine an automobile assembly line where each step along the line is undertaken by a different company with its own financial interest and separate labor union!… Present [construction] practice is impossible. The client asks an architect to design something specifically for him. In making drawings the architect will specify various components out of catalogues. He is nearly always restricted to elements that are already manufactured. Then the contractor, who has usually had nothing to do with the design process, examines the drawings and makes his bid. Industry supplies raw materials and components and has little contact with the contractor. The various building material manufacturers make their components totally independent of each other….It is an absurd industry.”

Moshe Safdie, internationally renowned architect

General structure of construction projects

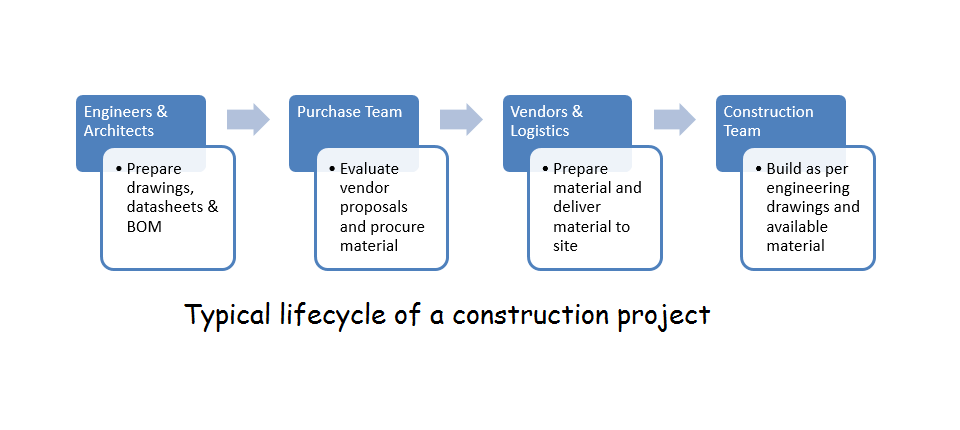

The lifecycle of a typical construction project starts at ‘design’ stage. Depending on what is to be built, either an Architect or an Engineering Consultant designs the facilities. From this design, a bunch of engineering drawings and a bill of material is produced. Technical specifications, drawings and bill of materials (BOM) are handed over to the construction contractor.

This contractor then approaches multiple vendors and procures the material as per bill of materials (BOM). Most of the material is available off the shelf. But some special equipment may sometimes need to be manufactured by the vendors.

Most of the material is available off the shelf. But some special equipment may sometimes need to be manufactured by the vendors. The material is then dispatched by vendors and received by the store manager at site.

The material on site is finally used to build the facilities as per the engineering/architectural drawings produced by the consultant.

Multiple different stakeholders

So in any project, there are many different stakeholders managing each stage out of – design – procurement – logistics – construction etc. Usually, there is a central figure of a project manager or EPC contractor who can coordinate between these different parties handling different parts of a project.

Communication via standard documents and drawings

Most of the technical communication between engineers – buyers – vendors – store manager – construction supervisor, happens through a bunch of technical drawings, specifications, datasheets etc.

Even small errors or miscommunication in these drawings can have huge implications in cost and efforts involved in actual construction.

For example, the majority of the cost in process industry plant construction goes in piping. Selecting a slightly higher pipe size or simply selecting a higher thickness of pipe can add a lot to the overall project cost.

Each project is different

Unlike the assembly line production, where exactly the same product is produced, again and again, all construction projects are different from each other.

There are many reasons for this – owners may have specific requirements, site conditions are different, different suppliers will provide different kinds of material.

In assembly line manufacturing a one-time design of each part, goes into thousands of products. Accordingly, design, making and purchase of each part receives a lot of attention.

That is not the case with construction.

Material inventory

Inventory planning done in manufacturing cannot be completely applied construction projects. Again, because it is a one-off product.

But without that kind of planning, timely availability of materials on site is always questionable.

Design changes possible during construction

Since each construction project is a unique product being built for the first time, there can be surprises all through the project life. Changes can come from – site conditions, material availability, material suitability etc.

Whenever there is a change, it can have rippling effects for different stakeholders.

Need for clear communication

When many stakeholders work on the same project, they definitely need smooth lines of communication. Since changes and surprises are quite common in construction projects, project managers must account for them and prepare to minimize their effect. One way to do that is to encourage quick and direct communication between the different stakeholders.

Additionally, if there is potentially a high cost for small miscommunication, then project managers must invest to facilitate clear and direct communication.

So even if we look at construction as a variant of manufacturing, it becomes easy to see how different the challenges with construction projects are.

Consequently, it also becomes obvious, why the tools originally designed for managing manufacturing processes, fail when implemented for construction projects.

WorkPack for Construction Projects

Following this philosophy at WorkPack, we have helped engineering & construction managers from many different verticals to streamline their project execution.

WorkPack emphasizes on facilitating the communication at ground level personnel who are performing the actual work – engineers, architects, buyers, site supervisors, auditors, store managers etc.

You can radically improve the productivity of your project team simply by fixing the communication gaps. Write to us and let us know if you would like to set up a consulting session with our projects team.

No Comments